Laminate Plywood Process

Laminate Plywood are actually engineered wood that’s made by glueing thin veneer sheets together, with a resin and under high pressure. This Laminate Plywood creates a thick, strong and flexible flat sheet. It’s usually preferred over solid wood, as it’s cheaper and less likely to warp or shrink over time.

This versatile material has numerous uses, both in your interiors and exteriors (sheathing). You can use waterproof laminated plywood in your partitions, cabinetry, ceilings, wardrobes and even your floors!

If you’re a fan of decor, waterproof laminate plywood can even prove to be great for decorative elements such as wall panelling, cladding and arches. However, it’s important to note that there are different types of plywood, each with grades that suit different purposes.

Plywood can be laminated, which is a procedure that combines many layers of plywood to produce a material that is thicker, stronger, and more resilient. A detailed tutorial on laminate plywood can be found here.

1. Gather Materials

Laminate plywood is great for turning plywood into a great looking piece of wood or furniture. It also can add durability, and water resistance to your countertops. There are three basic elements: Vaneer, glue, and a substrate (usually plywood, mdf, or strong stiff material to bear the load).

2. Prepare the Plywood

Ensure that the plywood sheets are clean, dry, and free from any dust or debris. Sand down any rough edges or surfaces to create a smooth bonding surface.

3. Cut The Laminate

Cut the laminate slightly larger than the size of the substrate. I like a quarter inch on each side.. In this instructable I will be using strips of laminate which were cut using a table saw to finish the exterior of a cabinet, arrange the laminate on a temporary surface such as scrap wood or newspaper. That way when the glue inevitably drips, it isn’t permanently attached to your work surface. It helps to tape down the edges of the laminate being aware of your margin. Remember that some laminates and vaneers are brittle against the grain and the worst thing is to finish laminating a large surface only to get a chip or small break.

4. Apply Glue

Using a roller or brush, apply a thin and even layer of wood glue to one side of the first plywood sheet. Make sure to cover the entire surface.

5. Layer Plywood Sheets

Place the second plywood sheet on top of the first one, aligning the edges carefully. Press down gently to ensure good contact between the two sheets.

6. Repeat

If you’re laminating more than two sheets together, repeat the process by applying glue to the top of the second sheet and adding additional sheets on top.

7. Clamp the Layers

Once all the plywood sheets are stacked together, use clamps to secure them firmly in place. Place the clamps along the edges of the plywood stack, ensuring even pressure across the entire surface.

8. Allow Drying Time

Leave the clamped plywood stack to dry for the recommended time specified on the wood glue container. This typically ranges from several hours to overnight, depending on the type of glue used.

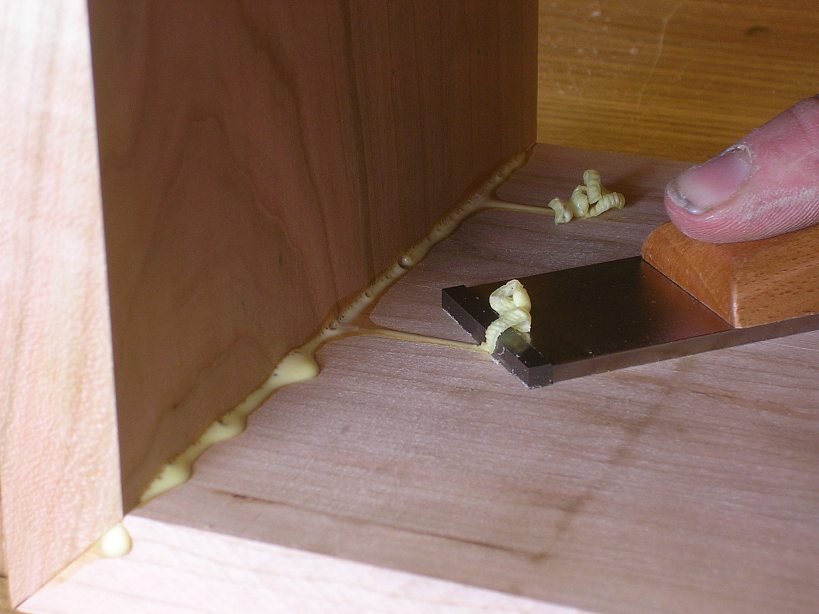

9. Remove Excess Glue

After the glue has dried, carefully remove any excess glue that may have squeezed out from between the plywood sheets during clamping. You can use a scraper or sandpaper to clean up the edges.

10. Trim and Finish

Once the laminate has dried completely, you can trim the edges of the laminated plywood to your desired size using a saw. Sand down any rough edges for a smooth finish.

11. Optional Sealing

If you’re using the laminated plywood for outdoor or high-moisture applications, consider applying a waterproof sealant or finish to protect the wood from moisture damage.

Finish !

Following these 12 steps should result in a well-laminated plywood panel that is strong, durable, and ready for use in various woodworking projects , good luck !

Is plywood good for furniture?

Yes, laminated plywood is a type of plywood that has a thin layer of laminate on one or both sides. The laminate can be made of plastic, paper, or wood veneer, and it can have different patterns, colors, or textures. Laminated plywood is usually more resistant to water than regular plywood, but it is not completely waterproof. Water can still seep through the edges or damage the laminate over time.

Therefore, laminated plywood is suitable for indoor applications where there is occasional exposure to moisture, such as furniture, cabinets, or flooring. However, for outdoor or wet areas, it is better to use waterproof plywood, which is specially treated with chemicals or resins to prevent water absorption and decay. Two common types of water-resistant or waterproof plywood are marine plywood and exterior-grade plywood.

Check out VHome products they have a variety of plywood products with the best range at affordable prices. Life-long certified products with the latest trends and hand-picked masterpieces.